Imagine a single, unassuming module on a factory floor - a simple bar-shaped robot capable only of crawling forwards and backwards. Then imagine it finding others and connecting with magnetic clicks - forming a larger machine like a complex three-dimensional tetrahedron that moves in new ways.

Finally, imagine this newly formed machine consuming another stray module - not for fuel, but for function - and integrating it to become faster and more capable. This isn't the cult sci-fi movie Screamers; it's the definitive start of an entirely new and revolutionary industrial paradigm that will reshape our future.

The news

Researchers at Columbia University have revealed a system demonstrating "robot metabolism" - a foundational step toward creating a completely self-sustaining robot ecology.

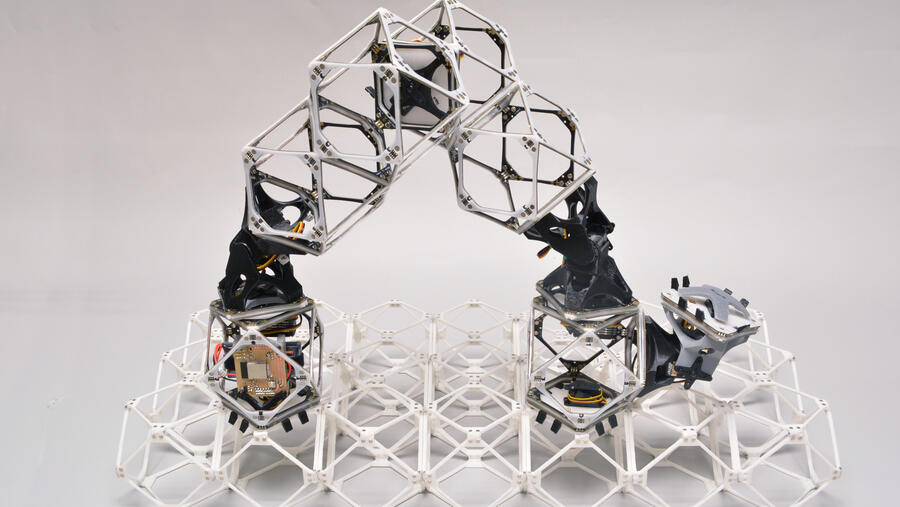

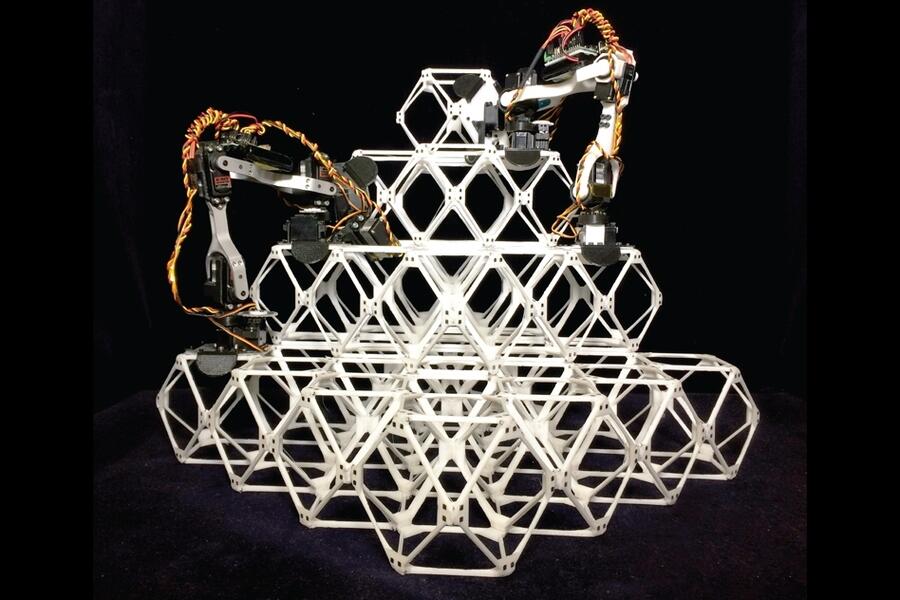

Their "Truss Link" modules are designed as simple building blocks that can self-assemble, grow, and adapt by consuming parts from their immediate environment.

In a series of experiments, these robots demonstrated the ability to develop from individual 1D components into fully functional 3D robots - without external machinery.

The system is capable of significant growth - developing from six individual links into a complex "diamond-with-tail" topology that then becomes a tetrahedron.

It can also self-repair by shedding a "dead" or non-functional link - and then integrating a suitable replacement it finds in the environment.

A view from the outside

While robot minds have evolved rapidly via artificial intelligence, their physical bodies have remained largely fixed and monolithic systems - unable to systematically integrate external materials.

This breakthrough tears down that wall - proposing a future where robots are open systems capable of physical growth, like infrastructure that self-repairs or autonomous fleets that adapt their form to new tasks on the fly.

However, lead author Philippe Martin Wyder notes the "high cost and manufacturability" challenges - with material costs exceeding US$200 per unit, creating a formidable capital gap.

The question is, who will fund the leap from nascent lab experiments to the mass-produced, low-cost modules necessary for a true robot ecology.

It's not just a tech question - it's an intrinsically geopolitical one - because when robots consume other robots to grow, the concept of industrial advantage changes.

The global race will no longer be for just superior AI, but also physical hardware that dominates an environment by absorbing the resources and machines around it.

We could see a new form of resource nationalism - well, perhaps we already are seeing it - a reality where nations hoard not just rare earths, but the fundamental building blocks of these robots.

Room for disagreement

To be clear, this future is distant and while its applications may be "inevitable" - they are still considered far-off, with researchers candid about their limitations.

Robot structures are still "very simple" - and control remains rudimentary, often requiring an operator with a keyboard.

The probability of a complex tetrahedron forming randomly without specific environmental assistance is currently zero - according to simulations which were conducted by the researchers.

The authors rightly argue that a "business case with a clear path to profitability" is required to spark the necessary industry adoption to overcome such immense hurdles.

Robot metabolism may remain a fascinating but ultimately niche academic pursuit for the foreseeable future.

Perspectives

The potential for profound disruption is so significant that key global sectors - such as logistics and manufacturing - are undoubtedly watching this development with keen interest.

But while Columbia's breakthrough represents pure research, the commercial reality is that modular robotics is already attracting serious venture capital attention.

Several companies are already positioning for the robot metabolism revolution:

Boston Dynamics (valued at $1.1 billion) has explored modular attachments for its Spot robot, though without self-assembly capabilities

Modular Robotics has raised $3.2 million for educational robot kits that hint at commercial applications

Universal Robots (acquired by Teradyne for $285 million) pioneered collaborative robots that could benefit from self-reconfiguring capabilities

MIT's Centre for Bits and Atoms has pushed the envelope further with self-replicating robot swarms that can assemble aircraft-sized structures.

Munich-based RobCo has raised $60 million from Sequoia Capital and Lightspeed Venture Partners, proving that investors see the writing on the wall - they're betting that modular, adaptable systems will dominate industrial automation for small and medium enterprises.

RobCo's $1,000-per-month robotics-as-a-service model demonstrates how modularity can democratise automation beyond the traditional industrial giants.

The established robotics powerhouses - ABB with its 400,000 installed industrial robots, KUKA's automotive assembly dominance, and Yaskawa's half-million global installations - suddenly find themselves in an interesting position.

Their monolithic systems may represent yesterday's thinking when startups like Unitree are forcing cost pressures with $1,600 robot dogs, and Tesla's Optimus promises mass production of humanoid workers by 2026.

It's a boon for the defense industry: truly autonomous, resilient, and adaptable machines that don't require human engineers for repair or reconfiguration in the field - they could literally rebuild themselves from battlefield debris.

While the single Truss Link on the floor is, for now, just a clever piece of engineering - its potential to connect, grow, and consume is immense.

CombineTesla's Optimus x RobCo's modularity x Columbia's self-assembly together and it could create the potential seed of a new ‘robo-industrial’ ecosystem.

The real question is: who will successfully build the robot that builds itself? The venture capital world is already placing billion-dollar bets.